Steel packaging solutions, particularly custom and sustainable options, are transforming shipping and logistics by offering exceptional strength, durability, and environmental benefits. Customization allows brands to create unique designs that enhance product protection, waste reduction, and brand recognition. Sustainable steel packaging is fully recyclable, contributing to reduced carbon footprints and aligning with growing eco-conscious demands. Advanced engineering and precision manufacturing ensure these solutions meet diverse industry needs while revolutionizing the shipping landscape.

In the realm of shipping and logistics, efficient and durable packaging is paramount. This article explores the multifaceted world of steel packaging solutions, delving into its various forms, benefits, and applications across industries. We dissect the allure of sustainable steel packaging and how customization in design can tailor-fit specific needs. Moreover, we highlight the advantages of steel over traditional materials and gaze into future trends shaping this robust sector.

- Understanding Steel Packaging Solutions for Shipping

- The Benefits of Sustainable Steel Packaging

- Customization in Steel Packaging: Tailoring to Your Needs

- Advantages of Steel Over Traditional Packaging Materials

- Applications: Industries Leveraging Steel Packaging

- Design and Production Processes of Steel Packages

- Future Trends in Steel Packaging for Shipping

Understanding Steel Packaging Solutions for Shipping

In today’s shipping industry, understanding steel packaging solutions is paramount for efficient and secure cargo transportation. Steel stands out among packaging materials due to its exceptional strength, durability, and resistance to damage, making it ideal for handling various goods across diverse climates and terrains. Moreover, embracing sustainable steel packaging offers a greener alternative to traditional materials, contributing to environmental conservation without compromising performance.

Customizing steel packaging to meet specific product and shipping requirements is another significant advantage. Manufacturers can design steel containers in various shapes and sizes, ensuring optimal protection for fragile or peculiar items. This adaptability not only enhances safety but also reduces waste, aligning with the growing demand for eco-friendly sustainable steel packaging solutions that minimize the environmental impact of global trade.

The Benefits of Sustainable Steel Packaging

Steel packaging solutions have emerged as a leading choice for shipping and logistics due to their unparalleled strength and durability. However, beyond functional advantages, sustainable steel packaging is gaining traction as an environmentally conscious option. This shift towards green practices is driven by the growing demand for eco-friendly alternatives that minimize waste and reduce the carbon footprint associated with traditional packaging materials.

Custom steel packaging plays a pivotal role in this movement. Its versatility allows manufacturers to design innovative solutions tailored to specific product needs, ensuring efficient protection during transit while promoting sustainability. By choosing sustainable steel packaging, businesses not only contribute to a cleaner environment but also enhance their brand image as responsible corporate citizens.

Customization in Steel Packaging: Tailoring to Your Needs

In today’s competitive market, businesses are constantly seeking innovative and tailored steel packaging solutions to stand out. Customized steel packaging offers a unique advantage by allowing brands to create designs that perfectly align with their identity and product requirements. This level of customization ensures that every aspect of the package, from size and shape to print and finish, is optimized for the specific needs of the shipping industry.

Whether it’s a unique product shape or specialized printing, customizable sustainable steel packaging provides an opportunity to enhance brand recognition. By working with experts in the field, companies can develop packages that not only protect their goods during transit but also serve as a powerful marketing tool. This approach ensures that your products arrive in style, leaving a lasting impression on recipients and contributing to a successful supply chain experience.

Advantages of Steel Over Traditional Packaging Materials

Steel packaging is emerging as a preferred choice for shipping and logistics due to its superior advantages over traditional materials. One of the key benefits is its exceptional durability; steel packaging solutions can withstand extreme conditions, including harsh weather, rough handling, and diverse temperature fluctuations during transportation. This longevity reduces waste and the environmental impact associated with frequent replacements.

Moreover, sustainable steel packaging is an eco-friendly option. Unlike many conventional materials, steel is recyclable, making it a responsible choice for businesses aiming to minimise their carbon footprint. Custom steel packaging also allows manufacturers to design innovative solutions tailored to specific product requirements, ensuring efficient protection and presentation.

Applications: Industries Leveraging Steel Packaging

Steel packaging has found its way into various industries, revolutionizing shipping and logistics processes. One of the key advantages is its versatility; it can be customized to suit specific product requirements, ensuring optimal protection during transit. From automotive parts to electronics, steel containers and pallets are ideal for heavy-duty applications due to their strength and durability.

The benefits of sustainable steel packaging are becoming increasingly recognized. Many companies are opting for steel as a greener alternative to plastic, contributing to reduced environmental impact. Customized steel packaging solutions allow businesses to enhance brand image by showcasing unique designs, making them stand out in a crowded market. This material’s longevity also minimizes waste, proving beneficial for both manufacturers and consumers alike.

Design and Production Processes of Steel Packages

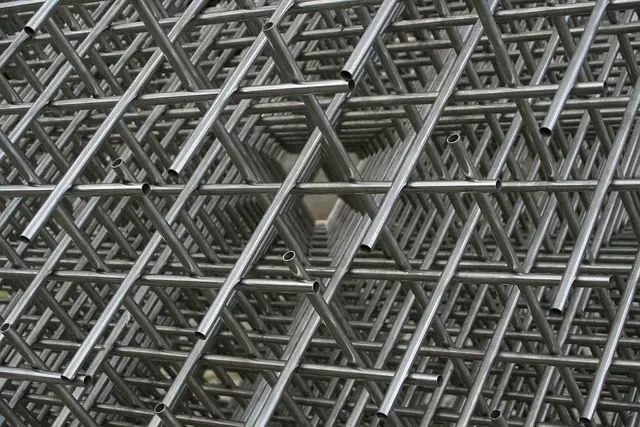

The design and production of steel packages are pivotal to creating effective and efficient shipping solutions. Steel packaging specialists begin by understanding client needs, leveraging advanced engineering software to draft custom designs that cater to specific product dimensions and shipping requirements. These designs incorporate innovative features such as reinforced corners, secure sealing mechanisms, and stackability, ensuring goods remain intact during transit.

Once approved, production involves state-of-the-art manufacturing processes that combine precision with sustainability. Steel sheets are cut, bent, and welded using advanced machinery to form containers, drums, or pallets. The use of sustainable steel packaging materials not only reduces environmental impact but also offers long-lasting durability, making it a superior choice for various industries. Customization options allow brands to incorporate their branding elements, enhancing product identification and market differentiation.

Future Trends in Steel Packaging for Shipping

The future of steel packaging for shipping is looking bright, with a growing emphasis on sustainability and innovation. One trend gaining momentum is the shift towards more sustainable steel packaging solutions. As environmental concerns continue to rise, manufacturers are exploring ways to reduce their carbon footprint, and steel packaging is at the forefront of this movement. The industry is embracing eco-friendly practices by utilizing recycled materials and implementing efficient production processes that minimize waste.

Custom steel packaging is another area expected to experience significant growth. With the demand for specialized and unique packaging solutions on the rise, manufacturers are investing in advanced technology to create tailored steel packaging designs. This trend allows businesses to enhance product presentation, improve brand identity, and cater to specific client needs, ensuring a competitive edge in today’s market.