Custom steel packaging offers a robust, versatile, and eco-conscious solution for various industries. Its strength, customization, and corrosion resistance are combined with recyclability to reduce environmental impact. This approach enhances product presentation, drives sales through branding, and promotes a circular economy. Increasing demand for unique steel packaging designs is driven by consumer awareness of its sustainability benefits, making it an attractive option for food, cosmetic, pharmaceutical, and automotive industries. Customization supports brand identity while addressing storage, transportation, and safety needs. The production process involves conceptualization, design, engineering, and quality control using recycled materials and advanced machinery. Despite initial costs and weight considerations, steel's longevity offers long-term savings. Future trends include consumer demand for fully recyclable options and technological innovations in automation, digitalization, smart packaging, and advanced materials.

Custom steel packaging is revolutionizing the way brands present their products, offering a versatile and durable alternative to traditional materials. This article delves into the world of steel packaging solutions, exploring its benefits for environmental conservation, creative applications across industries, and design considerations to enhance brand identity. We examine the manufacturing process, address challenges like cost and weight, and look ahead to future trends shaping this growing market. Discover why sustainable steel packaging is a game-changer in today’s eco-conscious world.

- Understanding Custom Steel Packaging: A Versatile and Durable Option

- The Benefits of Sustainable Steel Packaging for Environmental Conservation

- Exploring Creative Applications: Industries Adopting Steel Packaging

- Design Considerations for Custom Steel Packaging to Enhance Brand Identity

- Manufacturing Process: From Concept to Production of Steel Packaging Solutions

- Overcoming Challenges: Cost, Weight, and Recycling Concerns in Steel Packaging

- Future Trends Shaping the Custom Steel Packaging Industry

Understanding Custom Steel Packaging: A Versatile and Durable Option

Custom steel packaging is a versatile and durable solution that caters to a wide range of industries. It offers a unique blend of strength, versatility, and customization, making it an ideal choice for various product types and applications. Steel is known for its exceptional resilience and resistance to corrosion, ensuring that goods remain protected during transportation and storage.

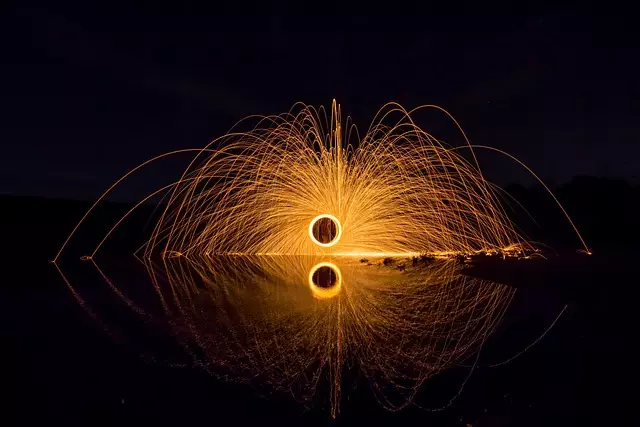

The use of sustainable steel packaging is also on the rise as businesses look for eco-friendly alternatives. Modern steel packaging designs can be recycled, reducing environmental impact and promoting a circular economy. Furthermore, custom steel packaging allows brands to create unique, branded containers that enhance product presentation and appeal to consumers. This approach not only improves product visibility but also adds value through distinctive branding, ultimately driving sales and brand recognition.

The Benefits of Sustainable Steel Packaging for Environmental Conservation

Custom steel packaging offers a compelling solution for businesses aiming to reduce their environmental impact. Sustainable steel packaging is not just about aesthetics; it’s a powerful tool in the fight against waste and climate change. This durable material can be recycled infinitely, meaning each piece of custom steel packaging has the potential to find new life, preventing the need for virgin resources and minimizing mining’s ecological footprint.

Furthermore, steel’s superior barrier properties make it an excellent choice for food and beverage packaging, extending product lifespans and reducing spoilage. By adopting sustainable steel packaging, brands can cut down on frequent repackaging, lower their carbon emissions, and contribute to a circular economy—all while maintaining the quality and appeal of their products in custom designs tailored to their unique branding.

Exploring Creative Applications: Industries Adopting Steel Packaging

In recent years, the demand for unique and innovative steel packaging solutions has been on the rise across various industries. This shift can be attributed to the growing awareness of sustainable steel packaging as a viable alternative to traditional materials. Steel’s durability, recyclability, and versatility make it an attractive option for brands seeking to reduce their environmental footprint while enhancing product presentation. Custom steel packaging allows businesses to stand out in a crowded market by creating visually appealing and distinctive designs that capture consumers’ attention.

Beyond the obvious applications in food and beverage, industries such as cosmetics, pharmaceuticals, and even automotive are increasingly adopting custom steel packaging. The versatility of steel allows for a wide range of shapes, sizes, and finishes, enabling brands to convey their unique identity and values through their packaging. As sustainability becomes a paramount concern for consumers worldwide, the adoption of sustainable steel packaging is expected to continue accelerating across multiple sectors.

Design Considerations for Custom Steel Packaging to Enhance Brand Identity

When designing custom steel packaging, a key aspect is enhancing brand identity. Visual appeal plays a significant role in attracting customers and conveying brand values. Steel packaging solutions allow for unique and durable designs that can be tailored to suit different product types and markets. Incorporating vibrant colors, sleek lines, and distinctive shapes ensures the packaging stands out on retail shelves, reinforcing brand recognition.

Moreover, sustainable steel packaging is an eco-friendly option that can appeal to environmentally conscious consumers. Steel’s longevity and recyclability make it a responsible choice for brands aiming to reduce their environmental impact. Customization options extend beyond aesthetics; package structures can be engineered to optimize storage and transportation efficiency while ensuring product safety and integrity. This holistic approach to design not only bolsters brand identity but also contributes to the overall sustainability of steel packaging solutions.

Manufacturing Process: From Concept to Production of Steel Packaging Solutions

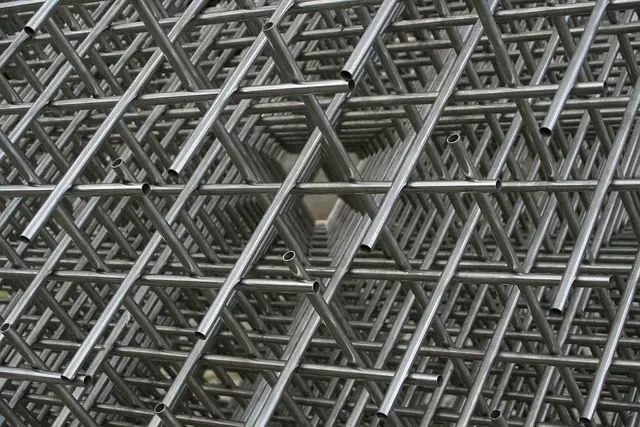

The journey of creating custom steel packaging solutions begins with a concept, evolving through meticulous design and engineering processes. Manufacturers start by understanding client requirements and environmental goals, ensuring every detail aligns with sustainability aspirations. This includes material selection, where recycled and recyclable steel is often the cornerstone, promoting eco-friendly practices without compromising quality or durability.

Once the concept is finalized, production kicks into gear. Advanced machinery and skilled technicians work in harmony to transform raw steel into intricate packaging designs. The process involves cutting, bending, stamping, and welding, each step meticulously executed to create robust and distinctive containers. From prototype testing to full-scale production runs, quality control measures guarantee precision and consistency, delivering top-tier sustainable steel packaging solutions tailored to specific product needs.

Overcoming Challenges: Cost, Weight, and Recycling Concerns in Steel Packaging

Custom steel packaging offers a range of benefits, but it’s not without its challenges. One of the primary concerns for many businesses considering steel packaging solutions is cost. Steel is often perceived as a more expensive material compared to traditional options like plastic or cardboard. However, when you factor in the durability and longevity of steel, the initial investment can pay off significantly over time, reducing waste and the need for frequent replacements.

Another hurdle is weight. Steel is inherently heavier than many alternative materials, which can impact transportation and storage costs, especially for businesses dealing with large volumes or products requiring efficient shipping. Yet, sustainable steel packaging excels in providing robust protection for goods while minimizing environmental impact. To address weight concerns, innovative manufacturing techniques have led to the production of lighter-gauge steels without compromising strength, making steel an increasingly viable option for various applications.

Future Trends Shaping the Custom Steel Packaging Industry

The future of custom steel packaging is poised for significant shifts, driven largely by a growing emphasis on sustainability and environmental responsibility. As consumers become increasingly conscious of their ecological footprint, there’s a rising demand for eco-friendly steel packaging solutions that minimize waste and maximize recyclability. This trend is expected to stimulate the adoption of innovative designs, such as fully recyclable and biodegradable steel alternatives, which offer both durability and environmental stewardship.

Technological advancements are also set to transform the industry. Automation and digitalization will play a pivotal role in enhancing production efficiency and precision. Smart packaging technologies, including sensors and connected devices, could become commonplace, enabling real-time tracking of product conditions during transportation. Moreover, the integration of advanced materials and coatings will improve steel packaging’s barrier properties, extending shelf life and enhancing product protection, thereby catering to diverse industry needs in a more sustainable manner.